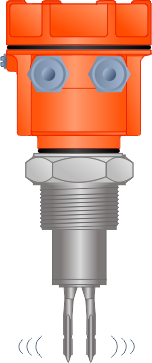

About LFV

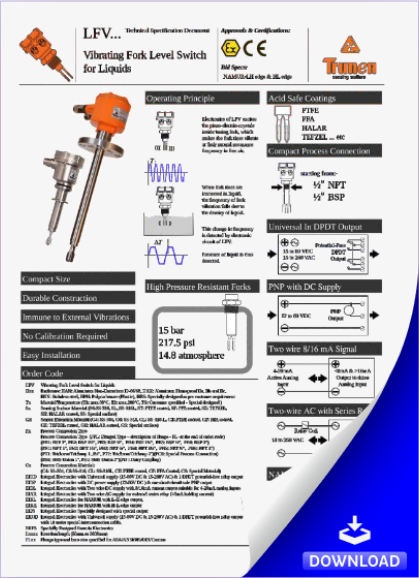

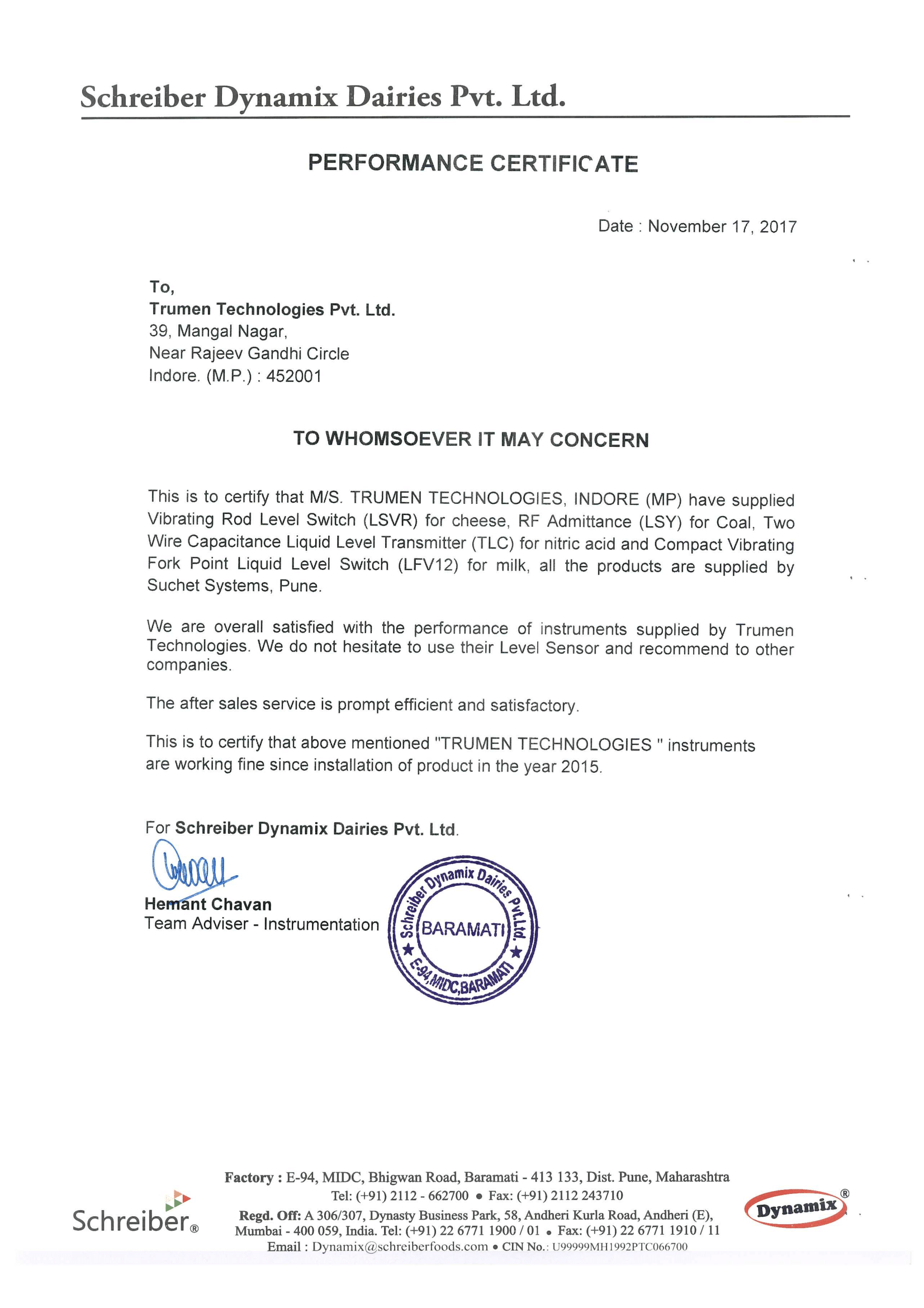

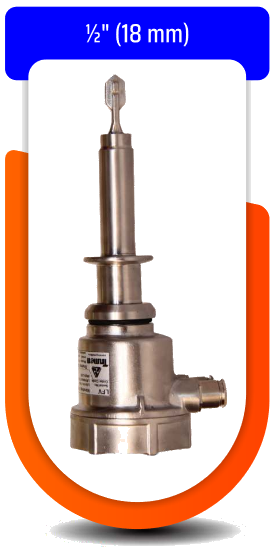

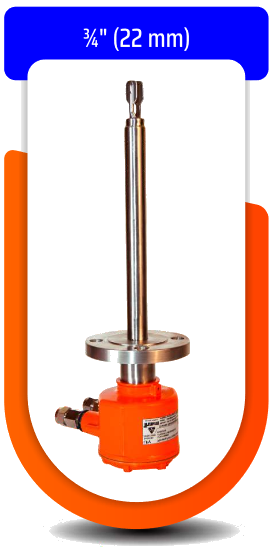

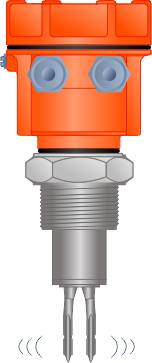

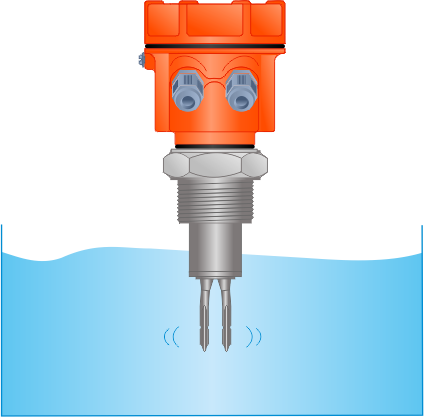

Trumen vibrating fork point level switch model LFV suitable for all types of flow able liquids in all process industries. It gives reliable measurement and does not affected due to material flow, vibrations in the tank, changing the media properties and material build-up in the sensor. Trumen LFV available in three different design like ½”, ¾” and 1” depends upon the mounting requirements.

Know MoreAbout Trumen

Trumen came into existence in 2009 and initially started with manufacturing of Tuning Fork Level Switches for liquid and solid applications. With time, the manufacturing range increased with addition of Capacitance Level Transmitter & Capacitance Level Switches, RF Admittance Level Switches, Rotating Paddle Level Switches, Conductivity Type Level Switches, Vibrating Rod Level Switches, Hydrostatic Level Transmitter, Radar.

Know More

Features

- Compact Size.

- Calibration-less operation.

- Universal power supply on same terminals (15 to 80VDC or 15 to 260VAC).

- Inbuilt settable switching delay 5 sec.

- Tropicalized sealed electronics module & easy to maintenance.

- Customized process connection threaded / flanged / hygienic & dairy fittings etc.

- Various output options like transistor PNP/NPN , NAMUR, 8/16mA current output. Etc.

Approvals

- CE Certification.

- IP-68/ 66.

- Exd Suitable for gas group IIC, T6 as per IEC 60079-1:2007 & IEC 60529:2001.

- Ex ia suitable for gas group IIC T6, as per, IS/IEC 60079-11:2006.

- Vibration test comply as per IEC standard 60068-Part 2-6.

- Functionality and environmental test of all instruments RFI-EMC, voltage transient and electrical functionality test as per IEC 61000.

Application

Trumen vibrating fork point level switch model LFV is used in different applications like -

- Trumen vibrating fork is used in different applications like, Water, oil, milk, chemicals, solvents and liquids having viscosity up-to 10,000Cp.

- Suitable for hazardous liquids & chemicals.

- Process temperature maximum 200° C / 250° C (available on requirement).

- Operating pressure 20 bar maximum.

Water

Milk

Oil

Chemicals

Operating Principle

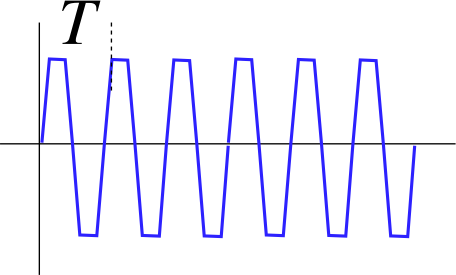

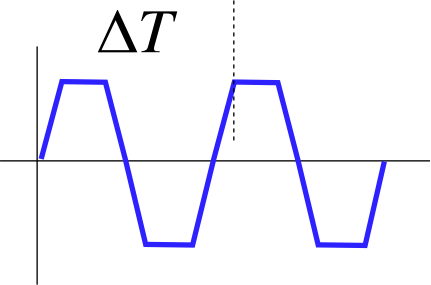

Electronics of LFV excites the piezoelectric crystals inside the tuning fork which makes the fork tines vibrate at their natural resonance frequency in free air.

When fork tines are immersed in liquid, the frequency of fork vibration falls due to the density of liquid.

This change in frequency is detected by the electronic circuit.

Operation

Device operation and settings:

Trumen LFV is very easy to operate

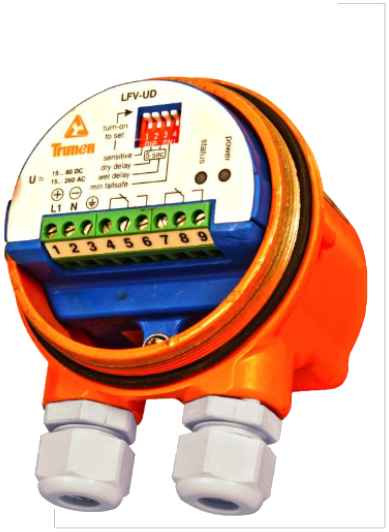

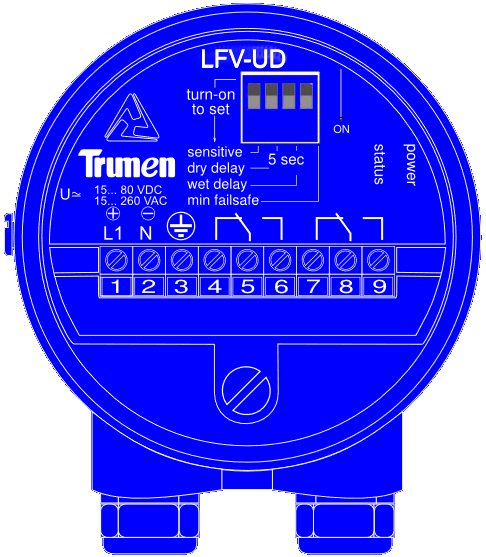

- Open the cover of Trumen LFV you can see there are 9 terminals. Terminal 1, 2 & 3 are for auxiliary power supply. Terminal 4, 5, 6 & 7, 8, 9 are for relay output.

- Connect the power supply either 15 to 80VDC or 15 to 260VAC on terminal 1 & 2 and plant earth on terminal number 3. Now switch on the power.

- Trumen LFV starts vibrating in air. Power LED is on and status level is in OFF condition.

- Now fill the liquid up-to the fork tines level.

- You can see the status LED of LFV is on means liquid reaches to the desired level.

- Now empty the liquid, you can see the status LED is OFF means material goes below the desired level.

- Relay status also change from NC to NO.

- There are 4 DIP switches provided on connection panel. Via DIP switch no.1 we can set the sensitivity that means if the density of liquid is low density fluids we need to on switch no.1 in this conditon LFV will sense the liquid. Keep it turned off for normal density fluids.

- Switch no.2 is to set dry delay means off delay. ON the DIP switch no.2 and empty the material. LFV will wait for 5 sec once the material goes below the sensor and after 5 sec it generates switching. During the delay cycle sensor ignore the turbulence.

- Switch no.3 is to set wet delay means on delay. ON the DIP switch no.3 and fill the material. LFV will wait for 5 sec once the material touches the sensor and after 5 sec it generates switching. During the delay cycle sensor ignore the turbulence.

- Switch no.4 is to set failsafe means the instrument should be in alarm condition if the sensor faces power failure. When the sensor is installed for high level keep the DIP switch no.4 is turned off i.e failsafe high or maximum and when the sensor is installed for low level keep the DIP switch no.4 turn on i.e. failsafe low or minimum.

- You can easily replace the electronics as shown

- In case of any further technical support please contact our sales and support team.

Connection Terminals

- + of DC or Live of AC Supply input

- - of DC or Neutral of AC Supply input Supply:15 to 80VDC or 15 to 260VAC 50/60Hz

- Earth terminal for safety

- Normally connected terminal of contact 1

- Common terminal of contact 1

- Normally open terminal of contact 1

- Normally connected terminal of contact 2

- Common terminal of contact 2

- Normally open terminal of contact 2

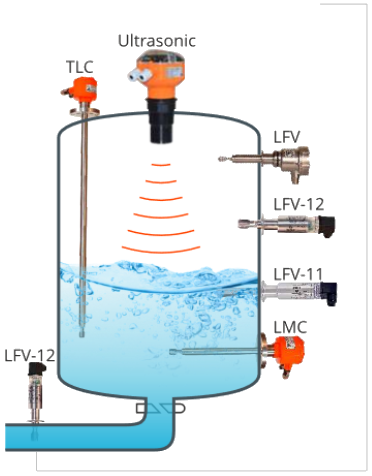

Typical Mounting

Product Video

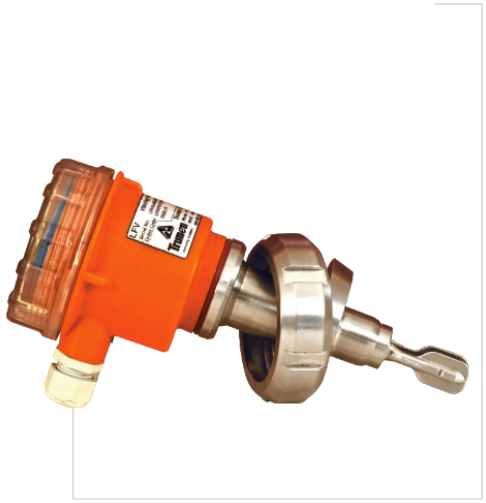

Testimonials

Trumen Export To

UK

UAE

Turkey

Tanzania

Poland

Malaysia

Lithuania

Macedonia

Iran

Italy

Denmark

Chile

France

Japan

Argentina

Kuwait

Canada

Sri Lanka

Korea

Thailand

USA